Sat, Jul 19, 2025

[Archive]

Volume 17, Issue 2 (June 2020)

IJMSE 2020, 17(2): 54-62 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Moussavi Janbesarayi S, Mohebi M, Baghshahi S, Ahmad Alem S, Irom E. Preparation of a Mesoporous Ceramic Adsorbent Based on Iranian Domestic Kaolin to Utilize as Slow-Release Urea Fertilizer Medium. IJMSE 2020; 17 (2) :54-62

URL: http://ijmse.iust.ac.ir/article-1-1622-en.html

URL: http://ijmse.iust.ac.ir/article-1-1622-en.html

Abstract: (17122 Views)

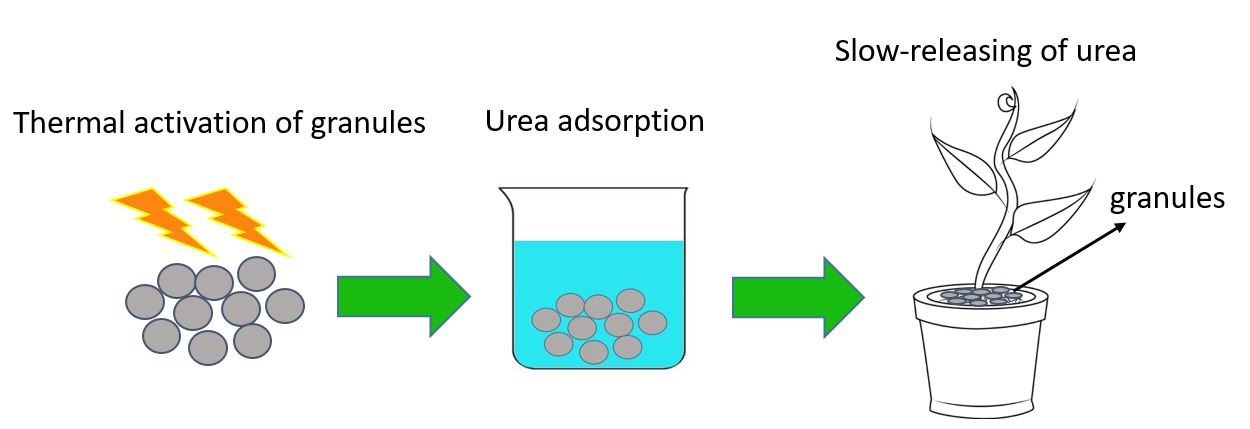

Overusing nitrogen fertilizer causes some serious problems for water resources, soil, and agriculture products. Researchers have been trying to develop effective means which may use less amount of fertilizers containing nitrogen. In this work, cost-effective ceramic granule adsorbent was prepared to be used as a fertilizer carrier of controlled release behavior. A mixture of 70 wt.% domestic kaolin and 30 wt.% gibbsite was used to produce the granules. By utilizing thermal analysis of raw granule, the calcination temperatures were obtained and the effect of various calcination temperatures of 500, 600, and 700˚C on the water adsorption was studied. The characteristics of granules were investigated by XRD, BET, FTIR, and SEM analyses. The results showed that by increasing the calcination temperature, the crystal structure of the granules was transformed into a dehydrated form and by calcination at 600°C the specific surface area of granules increased from 7.50 to 53.45m2/g. The granules were soaked in a 500g/lit solution of urea, where they adsorbed about 10wt.% urea. The dried urea-loaded granules were placed in water where the release of urea was measured by UV-vis spectrophotometry. Finally, different portions of urea-loaded granules were evaluated as fertilizer in the growing bed of corn plant where the height and the stem diameter of samples were compared with a control sample as well as a sample fertilized by urea directly. The results showed that by using the loaded granules, the urea consumption can be reduced by 50%.

Keywords: ceramic adsorbent, clay, gibbsite, nitrogen fertilizer, calcination, slow-release fertilizer

Type of Study: Research Paper |

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |