Mon, Feb 9, 2026

[Archive]

Abstract: (757 Views)

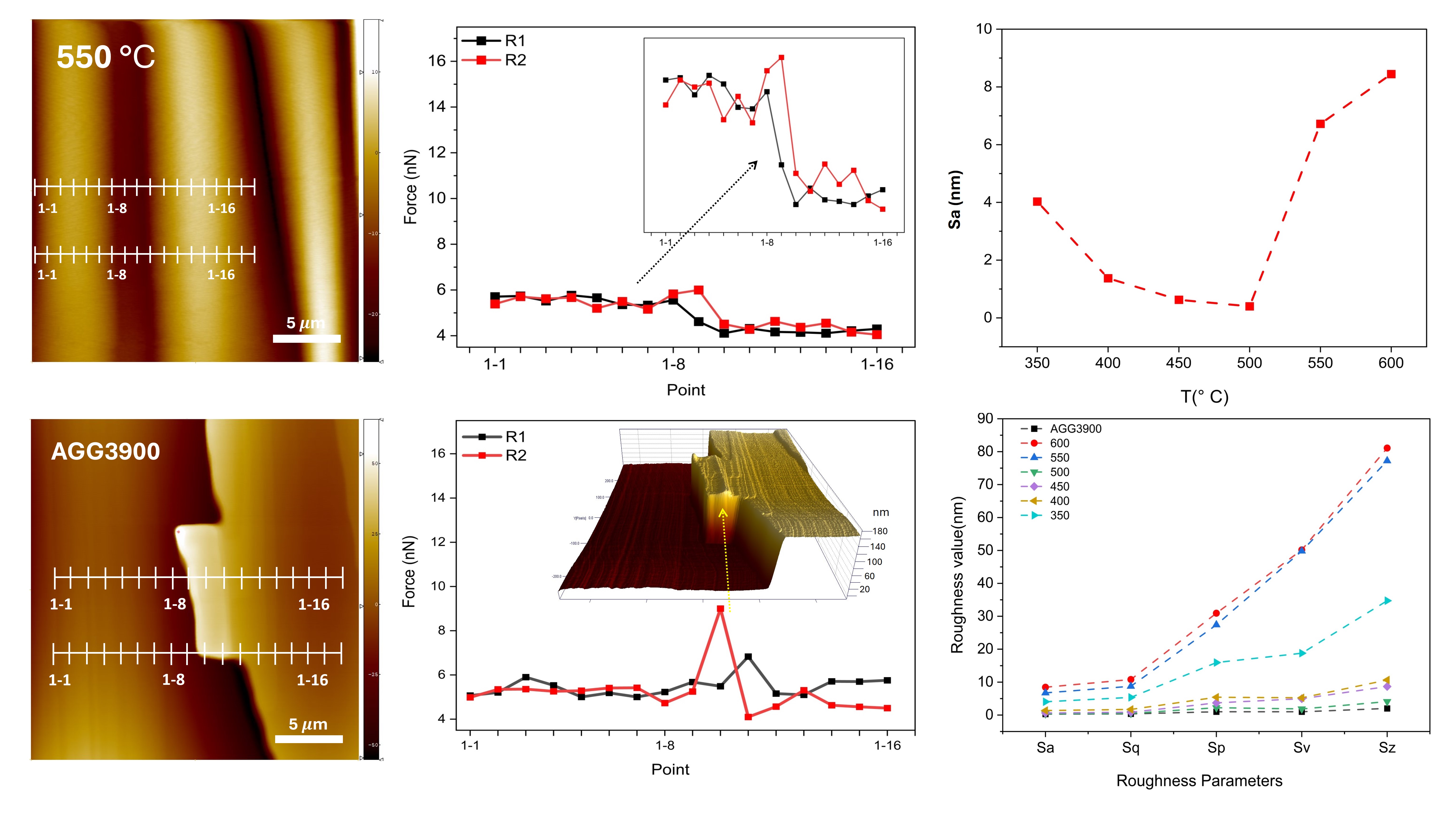

Potassium bromide (KBr) crystal structure attracts attention due to its various applications in electronic and optical devices as well as its potential in inducing local electrostatic fields. Fabricating this crystal via the conventional Czochralski method or more novel epitaxial methods is very costly. Here, with the focus on surface properties, a simple low-cost technique is employed based on the usage of KBr powder, pellet making, and pressure appliance for the fabrication of pellet crystals. These pellets have been annealed at various temperatures and studied via atomic force microscopy; morphologically and structurally. Our results demonstrate that increasing the temperature before the KBr melting point significantly reduces different roughness parameters, the height of the atomic steps, and the distance between them. At 500 °C, the atomic steps are more regular than at other temperatures, surface flatness and crystallinity are enhanced, approaching the quality of commercial single crystals. These modifications improve the quality of the crystals significantly, for various applications. Force spectroscopic measurements across atomic step edges of KBr, demonstrates higher forces with respect to flat regions. These engineered steps could serve as nanoscale templates for directing the self-assembly of molecules or for creating spatially varying electrostatic potentials in 2D material heterostructures.

Type of Study: Research Paper |

Subject:

Ceramic Materials and Engineering

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |