Sat, Jul 19, 2025

[Archive]

Volume 21, Issue 4 (December 2024)

IJMSE 2024, 21(4): 151-162 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Hojjati Lemraski A, Sedaghat Ahangari Hossein Zadeh A, Naghizadeh R, Majidian H. Investigation of the Effect of Titanium Dioxide and Aluminum Titanate on Physical, Mechanical, and Microstructural Properties of Synthesized Cordierite. IJMSE 2024; 21 (4) :151-162

URL: http://ijmse.iust.ac.ir/article-1-3659-en.html

URL: http://ijmse.iust.ac.ir/article-1-3659-en.html

Abstract: (7206 Views)

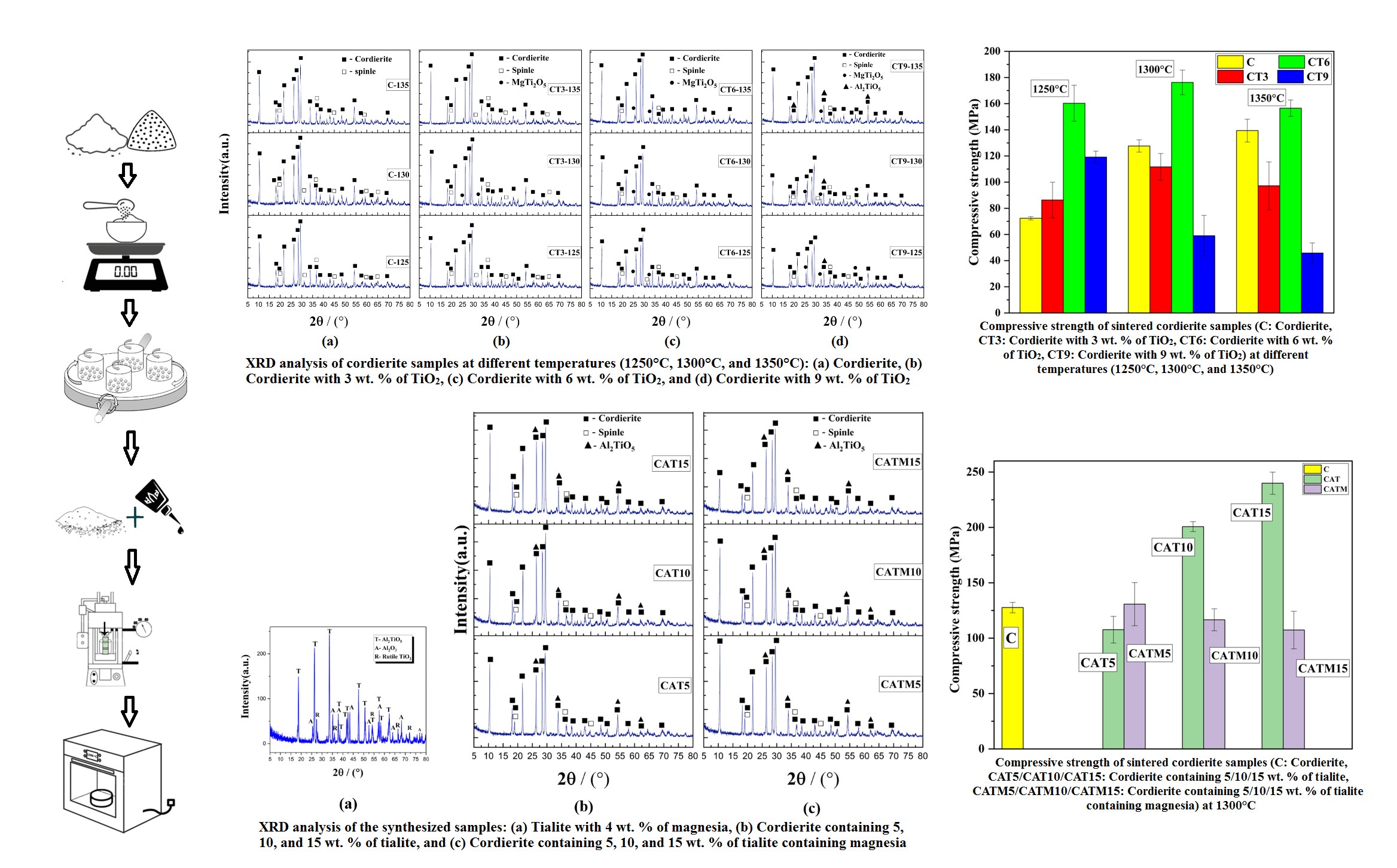

Cordierite ceramics are of interest for various applications due to their properties such as low thermal expansion coefficient and high thermal shock resistance. However, due to the narrow range of sintering temperature, attempts have been made to synthesize it using different additives. In this way, titania and tialite have been added in different amounts to the initial raw material mixture (talc, kaolin, and synthetic alumina). In this research, the initial powders (talc, kaolin, and synthetic alumina) were mixed in a planetary ball mill using different amounts of TiO2 and tialite. The mixtures were sintered at 1250, 1300, and 1350 °C for 3 h. X-ray diffractometry and fluorescence, thermal analysis, microstructural observation, density, and cold compressive strength (CCS) were used to evaluate the sintered samples. Phase analysis revealed the presence of the cordierite phase along with small amounts of spinel. With increasing sintering temperature and titania addition, the amount of spinel decreased and the amount of cordierite phase increased. The real density increased with increasing titania additive content, but at higher titania contents, microcracks were observed in the SEM micrographs. By adding 15 wt% of tialite to the initial batch, the compressive strength has been increased by 88% compared to the pure cordierite sample.

Type of Study: Research Paper |

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |